Episode Recap:

• AP Integrates design and manufacturing engineering with machine and tooling expertise. (0:03)

• Rapid prototyping and 3D CAD systems help CMM machines hold precise accuracy between departments. (0:13)

• These high-tech systems maximize customer service and satisfaction. (0:30)

• Advanced automation, robotics and computer controlled monitoring are critical to quality and production management systems. (0:46)

• Manufacturing schedules and replenishment are tied directly to inventory levels. (0:57)

• Wireless networks and tracking systems monitor parts through every step of manufacturing, assembly and stocking process. (1:08)

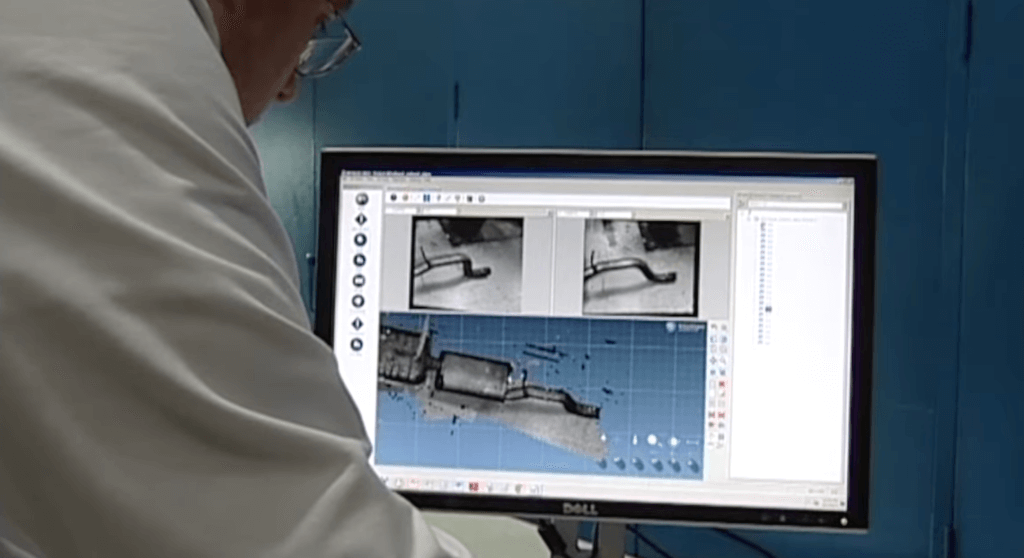

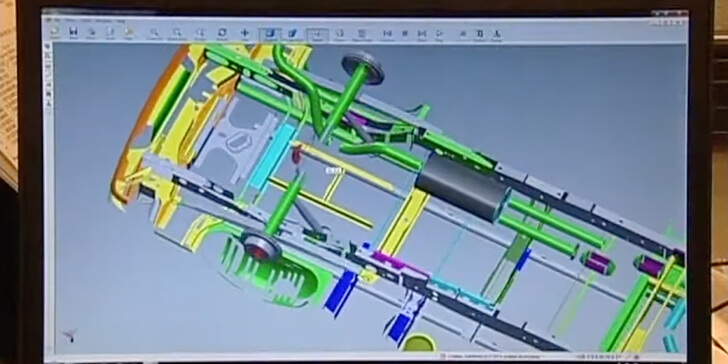

The foundation of the AP operation is the integration of design engineering, manufacturing engineering, and machine and tooling expertise. New developments in rapid prototyping and the use of SolidWorks’ 3D computer aided design systems that are integrated with CMM machines for precise dimensional measuring facilitate consistent accuracy between departments and expedite product development.

These pre-manufacturing aspects of the business create a solid platform for developing and maintaining the highest level of customer service and satisfaction by improving time to market and the continuous release of new products.

AP employs advanced automation, robotics and computer controlled monitoring, and statistical process controls as part of its quality and production management systems. The manufacturing schedules are tied directly to sales. As inventory levels change orders for those parts being sold are instantly sent to manufacturing for replenishment.

Wireless computer networks and barcode tracking systems monitor every part as it moves through the manufacturing and assembly processes and into inventory.

For more information, visit our website at apemissions.com